EUROVAC Vacuum Pumps

Private brand of Sun Kang Group

OVER 40 YEARS OF HISTORY

Now Aims To Open A New Future For Global Enterprises

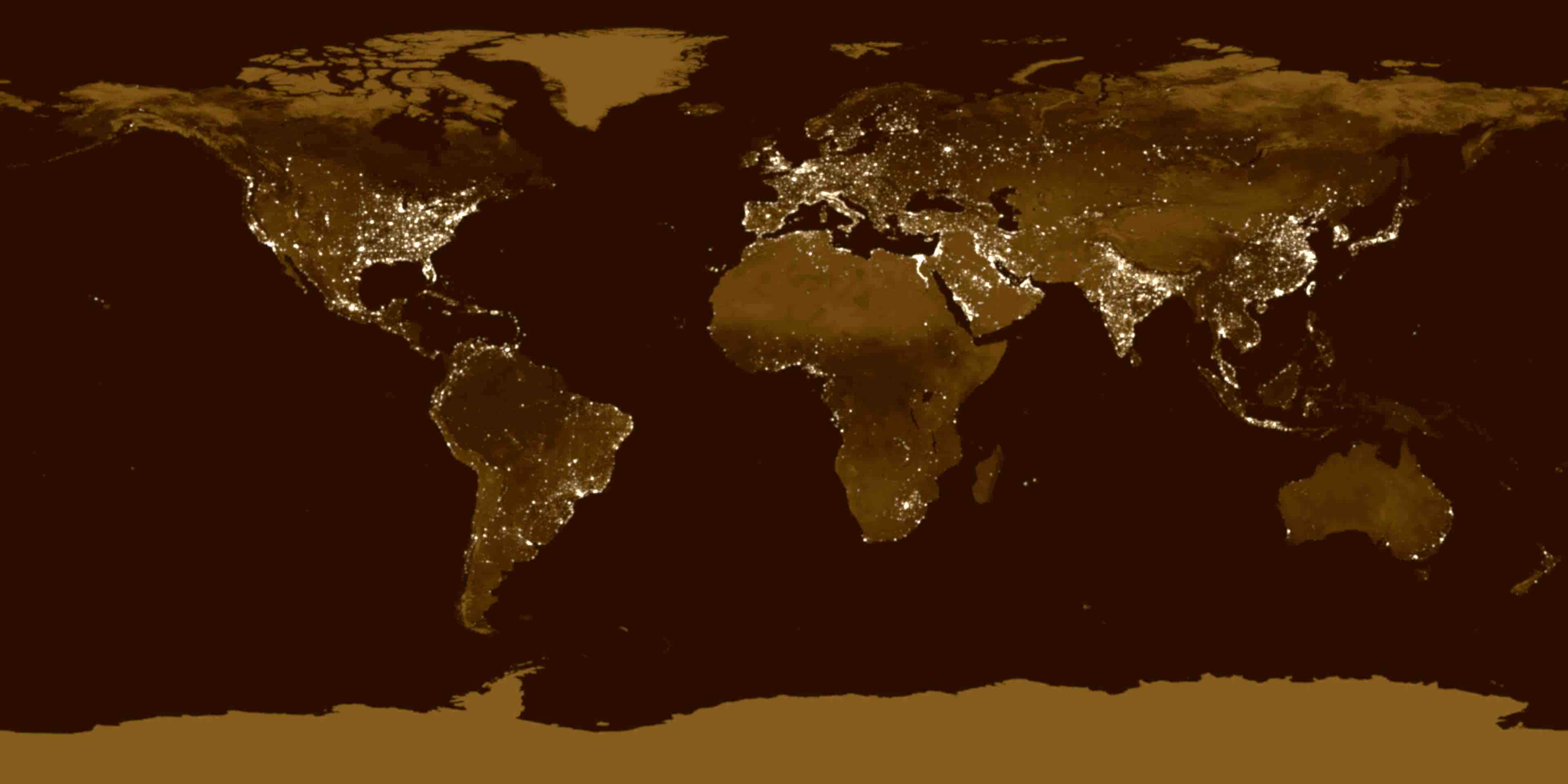

such as East Asia, Southeast Asia, Europe, Middle East, America and so on.

After years of development, EUROVAC has strong technical strength in the field of vacuum pumps and compressors.